Stamped concrete

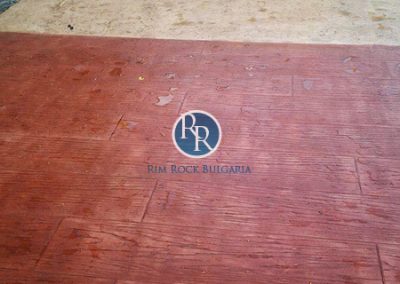

Stamped concrete – projects and production by “Rim Rock Bulgaria”

Stamped concrete began to be used in the 1950s in the United States.

The term “Stamped concrete” unites all techniques in which ordinary concrete, colored and treated with a stamp takes on the appearance of stone, wood or rock.

Stamped, horizontal and vertical concrete (also called decorative) has a wide application, as a type of flooring or for lining: plinths, fences, steps, external / internal walls, ceilings, columns, beams, countertops, fireplace facades and others.

We have a variety of prints, reliefs, textures and colors with exceptional resistance and durability.

RIM-ROCK BULGARIA makes its objects professionally, strictly observing the technology and deadlines, without compromising on the quality and the requirements of its customers.

Stamped concrete is chosen and preferred for its qualities.

8 advantages of the material

-

Budget optimization, the price compared to natural materials is many times lower

-

Possibility of speed production, fast installation

-

Flexibility and diversity in terms of design

-

Enables freedom in creating natural shapes

-

Ability to adapt to user requirements

-

Aesthetically maintained successfully recreates natural stone, wood, brick, paving

-

Easy maintenance

-

Longevity with proper maintenance

Stamped concrete, project by Rim-Rock Bulgaria

Read more

The ability of stamped concrete technology to resemble other materials makes it an optimal and cheaper alternative to them.

Technology of stamped concrete – basic steps in making

- field preparation

- installation of fittings

- laying and leveling of the concrete, with a vibratory trowel

- coloring

- stamping

- washing

- sealing

We have a well-trained team, expansion joints, drainage of the surfaces are provided, and the thickness and reinforcement of the concrete is determined according to the expected load.

The sealing layer is extremely important for stamped concrete, varnishes or impregnations are used for problem-free and long-term operation; additionally strengthens, protects against water penetration, preserves the colors and makes them more expressive.

It is characterized by alkali resistance, transparency, wear resistance and UV light protection.

Varnish for the stamped concrete is also part of the maintenance and the best protection. As a result of traffic and atmospheric effects, the varnish coating wears out, the stamped concrete loses its layer of shine, and a new protective layer should be applied periodically every 2-3 years. It is applied to a clean and dry surface. It dries quickly, refreshes the colors and protects the flooring.

To clean the concrete, do not use aggressive preparations and acids, they can damage the lacquer coating and the flooring.

Salt or lye for de-icing snow or ice would also destroy the surface layer of concrete, we recommend de-icers that do not damage concrete.

Production of stamped concrete at a temperature below 5 CoNOT recommended.